Hydraulic systems power heavy equipment across many industries. These systems depend on strong, leak-free connections to operate safely. A fitting links hoses, pipes, and components so that fluid moves under pressure without interruption. A poor choice leads to leaks, pressure loss, and mechanical damage. It is crucial to understand how to select proper fittings to help maintain reliable and efficient equipment.

The Basics Of Hydraulic Fittings

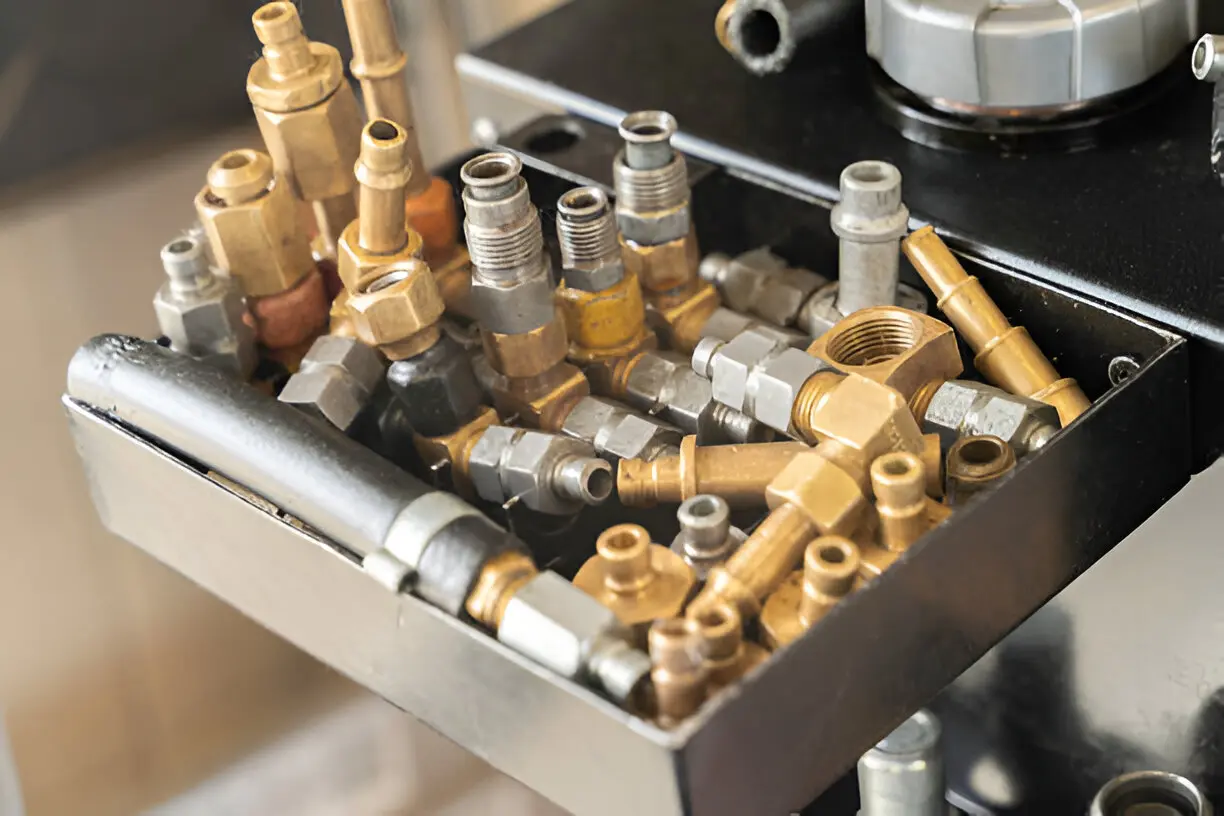

Hydraulic Hose and Fittings connect hoses and system parts to allow smooth fluid transfer. It keep systems sealed under high pressure and prevent leaks that lead to failures. They withstand heat, vibration, and heavy use. A clear understanding of how they work helps avoid costly issues.

- Types of Fittings: Adapters, couplings, and connectors each serve a specific function in hydraulic systems.

- Connection Methods: Threaded, flared, and quick-connect designs handle different pressure levels and assembly needs.

- System Integrity: Proper ones protect against leaks and pressure drops that lead to costly failures.

- Durability: High-quality products withstand heat, vibration, and tough conditions.

- Foundation for Selection: A good understanding helps match the right fit to its function and prevent system issues.

Types Of Hydraulic Fittings And Connections

Hydraulic fittings come in threaded, flared, and quick-connect forms. Threaded ones hold tight but need exact torque to avoid leaks. Flared and compression fittings work well for higher pressure levels and can be reused. Quick-connect designs suit systems that must be opened and reattached without tools. Each type must fit the task to work as intended.

Permanent fittings stay locked after crimping and resist leaks. Reusable ones can be removed and replaced without special equipment. Harsh conditions like dirt or moisture may call for more secure fittings. The correct type reduces downtime and repair costs. Each system benefits from fittings that match its pressure and use cycle.

Material Considerations

Fittings are available in steel, stainless steel, brass, and aluminum. Steel gives strength and is a cost-effective choice for most equipment. Stainless steel resists rust and suits use in wet or chemical-heavy areas. Brass works well in low-pressure systems and offers easy installation. Aluminum provides lightweight for mobile applications.

The right material must resist the fluid inside and the temperature outside. A wrong match causes corrosion or damage over time. High-pressure systems need strong metals to avoid bursts. The proper material prevents costly breakdowns. Good choices extend the service life of the hydraulic system.

Size And Compatibility

A correct size prevents leaks and maintains steady fluid flow. Using a size that is too small reduces flow and raises pressure. Oversized fittings create loose connections that fail under load. Standard size charts help select the right match for each hose. Thread type also matters because mixed threads can strip or fail.

Compatibility includes matching it with the right hose material and fluid type. Certain fluids react with metals and lead to corrosion. Pressure ratings must match to avoid hose separation or ruptures. It is imperative to check the size and compatibility before installation to avoid costly errors. Safe systems rely on precise measurements and correct matching.

Pressure Ratings And Performance

Each hydraulic system needs fittings that meet its pressure limits. Select the right rating to ensure steady operation and prevent leaks or bursts. Pressure charts from manufacturers provide the correct figures for safe use. Allow a margin above operating pressure for sudden spikes. This keeps performance stable under heavy loads.

- Pressure Matching: It must match or exceed system pressure limits.

- Flow Efficiency: Well-designed options reduce turbulence and maintain smooth fluid flow.

- Energy Savings: Proper fittings help pumps work efficiently and reduce energy costs.

- Equipment Protection: Stable pressure reduces strain on pumps, valves, and actuators.

- Safety Margin: Extra capacity prevents failures when pressure spikes occur.

Installation And Maintenance Best Practices

Correct installation starts with clean threads and proper torque. Cross-threaded or over-tightened options fail under stress. Manufacturer instructions specify exact torque levels to prevent leaks. A clean work area prevents dirt from entering the system. Proper tools reduce damage and ensure secure connections.

Regular checks keep systems safe and efficient. Inspect it for cracks, corrosion, or loose connections. Replace damaged parts before they fail under load. A written maintenance schedule helps track system condition. Careful inspection avoids unplanned shutdowns and keeps machines in service longer.

Cost And Long-Term Value

Low-cost options may save money at first, but lead to higher repair bills. Quality products reduce leaks, keep pressure stable, and lower downtime. Long-term savings come from fewer failures and less wasted fluid. Well-chosen fittings support smooth operation and consistent productivity. Good value comes from balancing price with reliability.

Cost decisions must reflect the system’s purpose. Expensive options may be justified where downtime is critical. Standard fittings may work well for light-duty equipment. Each choice should weigh risk, performance, and total cost. A focus on long-term reliability supports safe and efficient work.

Choosing the right hydraulic fittings keeps systems safe and reliable under pressure. Using Hydraulic Hose and Fittings that fit correctly prevents leaks and protects vital components. Regular inspection and timely replacement keep machines running at full strength. Careful selection reduces breakdowns and supports consistent performance over time.

Also Read-Online Lead Generation Techniques for Professional Services