Introduction

Modern industrial environments demand high agility, efficiency, and safety—elements that hinge on moving people, materials, and products seamlessly throughout the workspace. These objectives are increasingly supported through continuous advances in both technology and design. When companies invest in quality equipment and prioritize mobility, they see noticeable throughput and improvements in worker satisfaction. Using reliable tools, such as a rigid caster wheel, exemplifies how even the most minor component can make a substantive difference. Solid, high-performing casters help businesses maximize efficiency while significantly reducing workplace strain, fatigue, and downtime associated with moving heavy loads. By making conscious choices about such essential equipment, organizations lay the groundwork for safer, more productive operations.

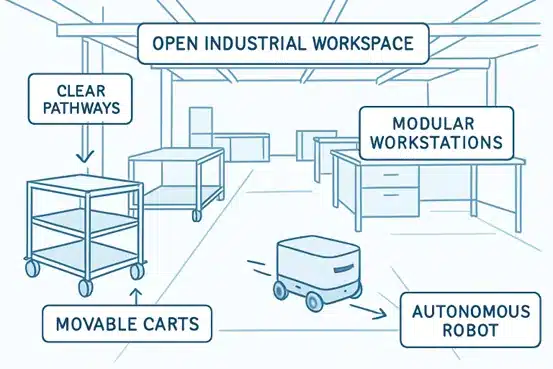

Creating effective mobility in industrial settings is about more than just acquiring new equipment—it requires a synthesis of thoughtful planning, practical implementation, and a strategic vision for growth. Swiveling carts, adaptable machinery, and optimized pathways contribute to better workflow, less physical exertion, and more consistent job satisfaction. Employees benefit from reduced manual handling, and management enjoys fewer errors and holdups. Strategic layout changes—including corridor widening and removing bottlenecks—are best complemented by investing in quality components for heavy equipment. This holistic approach maximizes operational flexibility and paves the way for increased competitiveness. The advances detailed in the sections below collectively form the backbone of a progressive, efficient industrial workspace strategy.

Integrating Autonomous Mobile Robots

Autonomous Mobile Robots (AMRs) are revolutionizing material flow in today’s industrial facilities. Equipped with sensors, vision systems, and artificial intelligence, AMRs can independently transport materials across large spaces and even interact with other robotic systems. From moving inventory between warehouse zones to delivering critical components to assembly lines, these robots dramatically increase the speed and accuracy with which items are transferred. Their ability to dynamically reroute themselves in response to obstacles or changing floor plans gives unparalleled flexibility to organizations facing evolving demands. Furthermore, integrating AMRs supports lean manufacturing by reducing the need for manual transport, limiting repetitive strain injuries, and allowing human workers to focus on higher-value tasks. Industry experts highlight that AMRs are especially effective for handling peak periods without requiring extensive labor increases, providing cost and safety advantages, as noted in Axios. As sensor and software technology advances, such robots will become standard in organizations seeking a competitive advantage through intelligent automation.

Implementing Modular Workstations

Adaptability is paramount on fast-paced production floors, and modular workstations deliver the required flexibility. Unlike fixed layouts that can bottleneck or slow shift changes, modular units are designed to be rapidly reconfigured without requiring extensive downtime or costly renovations. Employees can customize their stations with movable desks, adjustable shelves, integrated power supplies, and other tailored features. This encourages efficient multitasking, enhances comfort, and fosters innovation. Modular setups can be expanded or downsized quickly to suit group tasks, individual focus, or incoming projects, maximizing utility for each square foot of space. This improves day-to-day productivity and enables businesses to grow or pivot their processes without the overhead of major upgrades or long installation times. With built-in flexibility, companies can better accommodate varying team sizes, different product lines, or new technologies as they emerge.

Leveraging Integrated Workplace Management Systems

Integrated Workplace Management Systems (IWMS) provide an essential digital backbone for boosting and controlling industrial mobility in real time. These comprehensive platforms track resource utilization, asset locations, room bookings, maintenance schedules, and more, centralizing information that previously required manual input or disparate spreadsheets. Using live data, IWMS can alert facility managers to inefficiencies, identify underused equipment, and offer suggestions on efficiently reallocating resources. Predictive analytics can even anticipate when repairs are due, facilitating preventive rather than reactive maintenance. This comprehensive oversight streamlines operations, curbs unnecessary expenditures, and reduces operational downtime. In large-scale production environments, monitoring and adjusting everything from air quality to machinery usage at a glance gives management the confidence to support strategic and tactical decision-making, from workflow reorganization to facility expansion.

Adopting Ergonomic Material Handling Carts

Manual material handling, though essential, is a significant risk factor for injuries such as strains, sprains, and repetitive motion disorders. To combat these risks, modern ergonomic material handling carts are engineered to improve mobility, safety, and productivity. These carts feature ergonomic handles for multiple grip positions, lightweight and rugged frames, and top-quality casters that minimize push or pull force. Smooth-rolling wheels, including both swivel and rigid caster wheel options, allow easy maneuvering around corners or tight aisles, reducing the potential for accidents. Advanced models may include braking systems, adjustable shelves, and corrosion-resistant surfaces for greater functionality. Selecting carts made with durable materials such as reinforced polyethylene or coated steel ensures longevity, even in demanding environments. According to OSHA guidelines on material handling, equipping workers with the correct ergonomic tools yields fewer musculoskeletal injuries and helps streamline loading and unloading operations.

Enhancing Connectivity with Wireless Technologies

Modern industrial workspaces rely heavily on uninterrupted digital connectivity to power their operations. Enterprise-grade Wi-Fi networks provide the backbone for tablets, handheld scanners, automated guided vehicles, and wearable technology that assist with inventory checks, navigation, and communication. Businesses ensure comprehensive, reliable coverage—even in warehouses filled with metal structures or moving equipment by strategically placing wireless access points and integrating mesh networking. Advanced wireless technologies, such as private LTE networks, are now being deployed for their range and reliability benefits, especially in expansive or complex environments. Furthermore, integrated audiovisual (AV) systems support instant digital collaboration, allowing teams to share data, make decisions, and adapt to new information on the fly. This connectedness proves invaluable for distributed or multi-shift teams and ensures that technical gaps or communication delays don’t hamper productivity.

Designing Adaptive Workspaces

Adaptivity in industrial workspace design far exceeds the use of mobile furniture. It encompasses the utilization of mobile partitions, retractable barriers, and zones designed to alternate function throughout the day. For instance, a space may serve as a quality control area during the morning and transition into a team meeting space by the afternoon with minimal disruption. Investing in adaptive architecture makes it much easier to host project-based teams, train new employees, or accommodate surges in demand. As industries contend with increasingly unpredictable markets and rapid technological change, such spaces offer vital resilience. In addition to improving operational agility, adaptive environments promote creativity and teamwork, enabling business units to test, iterate, and optimize without significant capital investment in new square footage.

Prioritizing Employee Well-Being

Research continues to confirm that productive workforces are healthy workforces. Companies that prioritize their staff’s physical and mental health through improved workspace mobility and comfort features end up seeing significant returns in engagement and retention. Many forward-thinking organizations now incorporate wellness rooms, offer ergonomic seating and workstations, and provide environmental controls to tailor lighting, noise, or temperature to individual preferences. Designated break areas and quiet rooms allow employees to recharge, reducing stress and enhancing focus upon return. On-site fitness areas, access to outdoor spaces, and flexible break policies contribute to a supportive culture that values well-being. Organizations that actively foster such environments find it easier to attract top talent and minimize workplace accidents, absenteeism, and turnover. Investing in employee wellness isn’t just about meeting minimum standards—it’s about supporting your greatest asset: your people.

Investing in Sustainable Solutions

Sustainability has evolved from a compliance requirement into a driver for efficiency and innovation across industrial sectors. By selecting eco-friendly building materials, energy-efficient lighting, and low-VOC finishes, companies reduce their environmental impact and create healthier, more pleasant workplaces for their teams. Integrating innovative energy management systems—many of which tie directly into IWMS platforms—enables businesses to monitor and reduce their energy consumption and related emissions in real time. Some facilities now employ solar panels, LED lighting, and water reuse systems to shrink their footprint further and appeal to environmentally conscious clients. Efficient layouts that minimize unnecessary movement support sustainability by reducing energy use. Regular monitoring and transparent reporting, as detailed by the U.S. Environmental Protection Agency, reinforce long-term stewardship goals. Ultimately, these practices create a positive feedback loop—enhancing mobility, lowering costs, and boosting organizational reputation.

Read more: The Future of Contact Centers

Cart-to-Cart Migration Explained: How to Switch Platforms Without Downtime

Juan Soto’s Historic Contract with the Mets: A Shift in Baseball’s Financial Landscape?